আপনার উত্পাদন আপগ্রেড করুন: সিএনসি দোলন ছুরি স্পঞ্জ ফোম কাটার যথার্থ কাটিয়া এবং সহজ অপারেশনের জন্য

সিএনসি ভাইব্রেশন ব্লেড স্পঞ্জ ফোম কাটিয়া মেশিন: কলমের মতো সুনির্দিষ্ট হিসাবে নিয়ন্ত্রণ করা সহজ

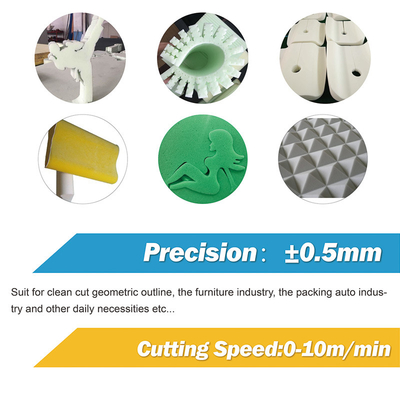

শিল্পগুলিতে যেমন নমনীয় উপাদান প্রক্রিয়াজাতকরণের ক্ষেত্রেপ্যাকেজিং, আসবাব এবং খেলনা, দক্ষতা এবং নির্ভুলতা প্রায়শই একই সময়ে অর্জন করা কঠিন।

সিএনসি ভাইব্রেশন ব্লেড স্পঞ্জ ফোম কাটিয়া মেশিনটি এই ব্যথার পয়েন্টটি সমাধান করার জন্য জন্মগ্রহণ করেছিল - এটি পুরোপুরি একত্রিত হয় "সুবিধাজনক অপারেশন"এবং"যথার্থ কাটিয়া"নরম উপাদান প্রসেসরের জন্য একটি আদর্শ সরঞ্জাম হয়ে উঠতে।

ব্যবহার করা সহজ, পরিচালনা করা সহজ:

বুদ্ধিমান নিয়ন্ত্রণ: ইন্টিগ্রেটেড অটোমেটিক কন্ট্রোল সিস্টেম, প্যারামিটার প্রিসেট, ওয়ান-বাটন স্টার্ট, ম্যানুয়াল হস্তক্ষেপ এবং অভিজ্ঞতার নির্ভরতা হ্রাস করে।

স্বজ্ঞাত সফ্টওয়্যার: ব্যবহারকারী-বান্ধব সফ্টওয়্যার দিয়ে সজ্জিত, মূলধারার সিএডি ডিজাইন অঙ্কনগুলির সরাসরি আমদানি সমর্থন করে, স্বয়ংক্রিয়ভাবে দক্ষ কাটিয়া পাথ উত্পন্ন করে, একটি বোতামের সাথে জটিল গ্রাফিক্সকে রূপান্তর করে এবং পরিষ্কার অপারেশন লজিক রয়েছে।

মিলিমিটারের সাথে সঠিক, সুনির্দিষ্ট কাটার একটি মডেল:

কম্পন ব্লেডের মূল প্রযুক্তি: ব্লেডটি উচ্চ ফ্রিকোয়েন্সিতে কিছুটা কম্পন করে, কাটিয়া প্রতিরোধের ব্যাপকভাবে হ্রাস করে।

এটি সহজেই স্পঞ্জ, ইভা, মুক্তো সুতি, ফেনা ইত্যাদির মতো নরম উপকরণগুলি প্রবেশ করতে পারে যেমন গরম ছুরি কাটার মাখনের মতো, মসৃণ এবং সোজা প্রান্তগুলি নিশ্চিত করে, কোনও বার্স, কোনও ইন্ডেন্টেশন এবং নকশার বিশদটি সঠিকভাবে পুনরুদ্ধার করতে পারে।

উচ্চ অনমনীয়তা কাঠামো + নির্ভুলতা সংক্রমণ: স্থিতিশীল যান্ত্রিক প্ল্যাটফর্মটি উচ্চ পুনরাবৃত্তিযোগ্যতা অবস্থানের নির্ভুলতা অর্জনের জন্য সার্ভো ড্রাইভ সিস্টেমের সাথে সহযোগিতা করে (সাধারণত ± 0.1 মিমি পর্যন্ত)। তবে এটি জটিল বিশেষ আকারের রূপগুলি বা মাল্টি-লেয়ার যথার্থতা কাটিয়া, এটি উপাদান বর্জ্য দূর করার জন্য স্বাচ্ছন্দ্যের সাথে করা যেতে পারে।

সিএনসি ভাইব্রেশন ছুরি স্পঞ্জ ফোম কাটিয়া মেশিনটি তার মানবিক অপারেটিং অভিজ্ঞতা এবং দুর্দান্ত কাটিয়া মানের সাথে নরম উপাদান প্রক্রিয়াকরণের মানকে নতুন করে সংজ্ঞায়িত করে। এটি জটিল কাটিয়া কার্যগুলিকে সহজতর করে এবং নাগালের মধ্যে নির্ভুলতা এবং দক্ষতা তৈরি করে - এটি বেছে নেওয়া মানে প্রযুক্তির ফলকটি সহজেই কেটে ফেলা এবং নমনীয় পদার্থের পর্যায়ে আনলিমিটেড সম্ভাবনাগুলি ব্যবহার করার জন্য বেছে নেওয়া।

প্রযুক্তির ডেটা:

| প্রযুক্তিগত ডেটা |

|

| প্রকার |

ডিটিসি-এসডি 2012 |

| সর্বোচ্চ পণ্যের আকার |

3000*2200*1250 (মিমি) |

| অনুভূমিক কাটিয়া ব্লেড |

2300*3*0.5 মিমি |

| উল্লম্ব কাটিয়া ব্লেড |

2300*3*0.5 মিমি |

| নিয়ন্ত্রণ ব্যবস্থা |

শিল্প কম্পিউটার+উইন্ডোজ এক্সপি ডি অ্যান্ড টি প্রোফাইলার সহ |

| কাটা গতি |

0 ~ 10 মি/মিনিট (সামঞ্জস্যযোগ্য) |

| শক্তি |

10 কেডব্লিউ, 380 ভি, 50Hz |

| ব্লেড টেনশন |

সিলিন্ডার টেনশনিং 6 বার |

| সামগ্রিক ওজন |

2000 কেজি |

| সামগ্রিক মাত্রা |

5800*3180*2400 মিমি |

কোম্পানির তথ্য

ফুয়াং ডি অ্যান্ড টি শিল্প কো।, লিমিটেড। সিএনসি ফোম কাটিয়া মেশিন উত্পাদন বিশেষজ্ঞ,

পলিউরেথেন কাটিং মেশিন, কুইল্টিং মেশিন এবং ফোম রিলেশন অ্যাসিস্ট্যান্ট

সরঞ্জাম।

আমাদের প্রকৌশলীদের গবেষণার মাধ্যমে, আমাদের কাটিয়া মেশিনটির সাথে ভালভাবে সংযুক্ত ছিল

জনপ্রিয় সিএডি এবং অর্জিত অটোমেশন এবং উচ্চ দক্ষতা,

উচ্চ নির্ভুলতা এবং এটি পরিচালনা করা সহজ করে তোলে।

আমরা সর্বদা গ্রাহককে প্রথম স্থানে রেখেছি এবং সন্তুষ্ট করার জন্য সর্বাধিক প্রচেষ্টা করি

আপনি। আমরা আন্তরিকভাবে অর্থনৈতিক বিকাশের অপেক্ষায় রয়েছি,

আপনার সাথে প্রযুক্তিগত এবং বাণিজ্য সহযোগিতা।

পণ্য: দ্রুত তারের কাটিয়া মেশিন, পিইউ কাটিং মেশিন,

গরম তারের কাটিয়া মেশিন, ইপিএস কাটিয়া মেশিন,

quilting মেশিন এবং আরও।

1। প্রশ্ন: আপনি কি কারখানা?

উত্তর: হ্যাঁ, আমরা 2006 সাল থেকে একজন প্রস্তুতকারক এবং ফোম মেশিনগুলি করছি।

2। প্রশ্ন: আপনি কোন অঙ্কন সফ্টওয়্যার ব্যবহার করেন?

উ: অটো ক্যাড।

3। প্রশ্ন: আপনার ইঞ্জিনিয়ার মেশিন ইনস্টল করার জন্য আমাদের কারখানায় আসতে পারে কিনা?

উত্তর: হ্যাঁ, নিশ্চিত।

4। প্রশ্ন: আপনি আমদানি করতে পারেন?ডিএক্সএফ ফাইলঅন্য উত্স থেকে?

উত্তর: হ্যাঁ যে কোনও ডিএক্সএফ ফাইল গ্রহণযোগ্য।

5। প্রশ্ন: অন্যান্য দ্রুত তারের মেশিনে ধূলিকণা নিষ্কাশন এবং ফিল্টারিং ছিল। এই মেশিনের কি ধুলো উত্তোলন রয়েছে?

উত্তর: হ্যাঁ, এটি অন্তর্ভুক্ত করুন।

Q .. প্রশ্ন: আপনি কোন দেশে বিক্রি করেছেন?

উত্তর: কানাডা, মেক্সিকো, ব্রাজিল, অস্ট্রেলিয়া, সিঙ্গাপুর, মালয়েশিয়া, সংযুক্ত আরব আমিরাত, ইয়েমেন, কাতার, আলজেরিয়া ইত্যাদি

7। প্রশ্ন: মেশিনে কোন সুরক্ষা নিয়ন্ত্রণ রয়েছে?

উত্তর: দুর্ঘটনার জন্য কন্ট্রোল বক্স এবং মেশিনে জরুরিতা বোতল রয়েছে মাহিকন বন্ধ করার জন্য।

কাটিয়া ফ্রেমের চারপাশে দুটি বেড়া রয়েছে, আপনি যখন বেড়াটি খুলবেন তখন মেশিনটি বন্ধ হয়ে যাবে।

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!